Quality management

Quality management. Sounds a bit stuffy, doesn’t it? Like something only serious, suit-wearing folks in boardrooms worry about. But the truth is, quality management is about making sure things are done right, whether you’re running a multinational corporation or baking a cake.

Think of it this way: you wouldn’t want to eat a cake that’s burnt, would you? Or drive a car that might fall apart on the highway? That’s where quality management comes in. It’s about setting standards, checking things are up to scratch, and making sure everyone’s on the same page.

What exactly is Quality Management?

In a nutshell, quality management is a structured approach to ensuring that products, services, and processes meet defined standards of excellence. It’s about consistently delivering value to customers and stakeholders.

Why is Quality Management Important?

:max_bytes(150000):strip_icc()/TermDefinitions_quality-management-76b2d39131b44d198151c167bf663652.jpg)

Happy Customers: When you deliver high-quality products or services, customers are happy. Happy customers become repeat customers, and they tell their friends.

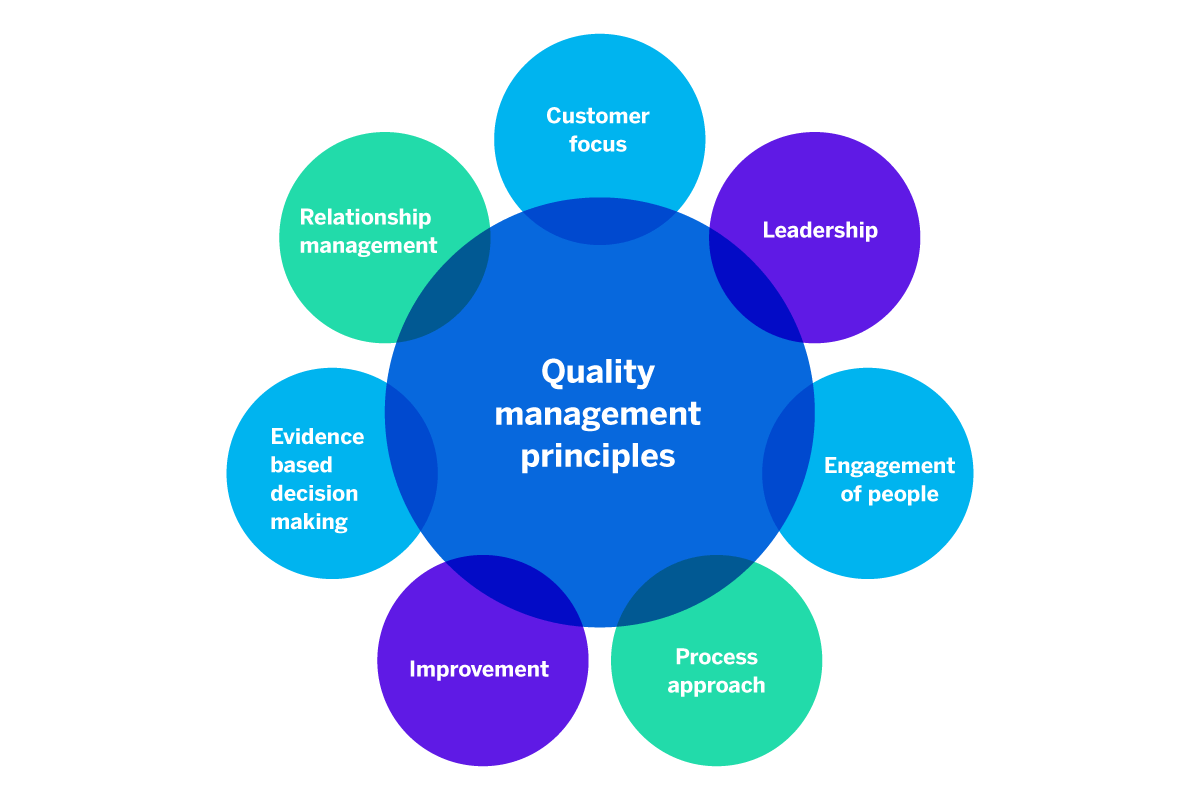

Key Principles of Quality Management

Several key principles underpin effective quality management systems:

Customer Focus: Understanding and meeting customer needs and expectations is paramount.

Quality Management Tools and Techniques

A variety of tools and techniques can be used to implement and improve quality management systems:

Six Sigma: A data-driven methodology focused on reducing defects and improving process efficiency.

Quality Management in the Real World

Quality management principles are applicable in a wide range of industries and contexts:

Manufacturing: Ensuring the quality of raw materials, production processes, and finished goods.

Implementing a Quality Management System

Implementing a successful quality management system requires careful planning and execution. Here are some key steps:

1. Define Goals and Objectives: Clearly define what you want to achieve with your quality management system.

2. Conduct a Gap Analysis: Identify the gaps between your current practices and desired outcomes.

3. Develop a Quality Policy: Create a written statement outlining your organization’s commitment to quality.

4. Establish Procedures and Processes: Develop clear procedures and processes for all key activities.

5. Train Employees: Provide employees with the necessary training and resources to perform their jobs effectively.

6. Monitor and Measure Performance: Track key performance indicators (KPIs) to measure progress and identify areas for improvement.

7. Conduct Regular Reviews: Conduct regular reviews of your quality management system to identify areas for improvement and ensure ongoing effectiveness.

The Importance of Continuous Improvement

Quality management is not a one-time event. It’s an ongoing journey of continuous improvement. Regularly review your processes, gather feedback from customers and employees, and make adjustments as needed.

Conclusion

Quality management may sound like a complex topic, but it’s really about common sense. By focusing on customer needs, empowering employees, and continuously striving for improvement, you can build a culture of quality that benefits everyone. Remember, quality is not just about meeting standards; it’s about exceeding expectations.